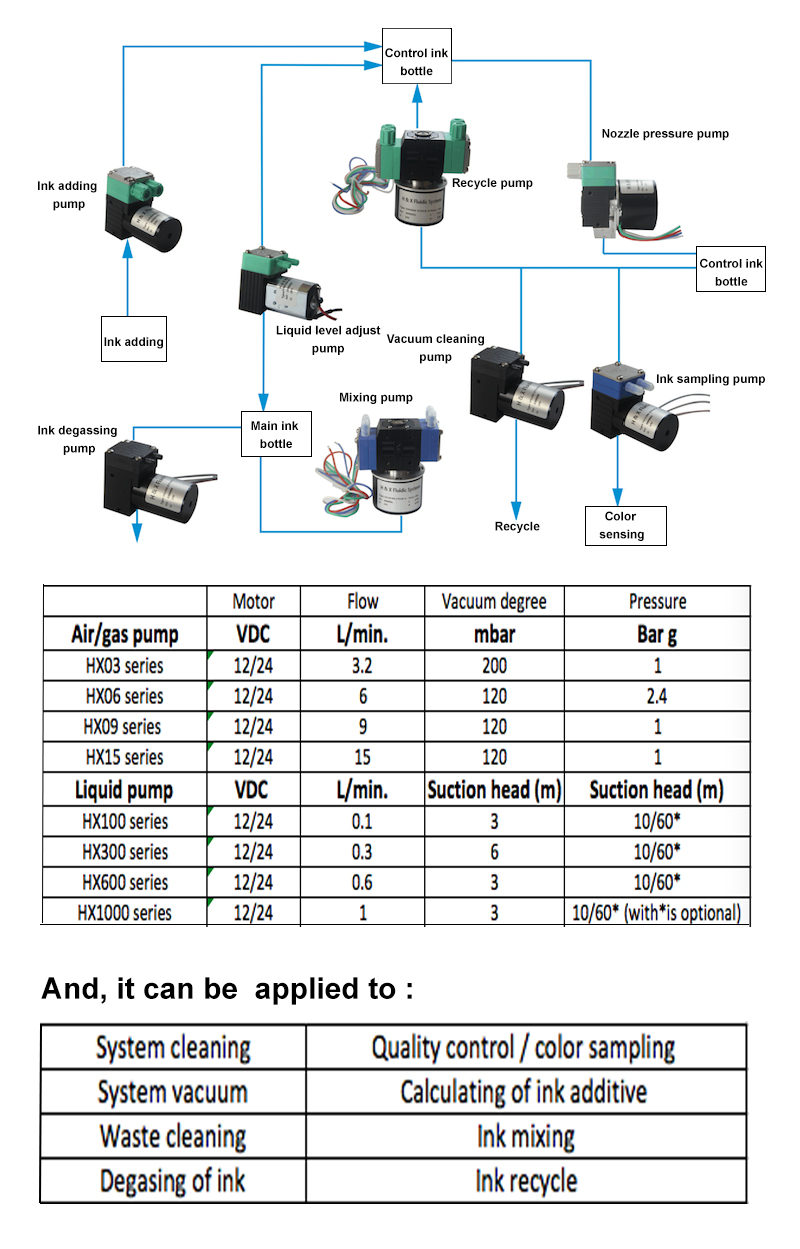

Joto Fluid is the leading pathfinder for diaphragm pump designing and manufacturing. Our pumps can be used to transport liquid and gases/air, and available for both vacuum and pressure applications. We provide tailor-made solutions based on the complex requirements of customers. Our liquid diaphragm pumps are designed to be simple and economical, requiring no hoses to run various functions. This avoids unbalanced flow caused by aging of the tubing or worse tubing rupture. This will not confuse the ink. This type of pump does not require replacement of the tubing and does not cause expensive ink waste.

The liquid pump is self-priming and is especially suitable for vacuum or pressure applications. They are ideal for low viscosity inks and can run continuously without aging. No leakage will occur under any bad working conditions. For corrosive inks, corrosion resistant materials such as nylon, PTFE, PVDF, EPDM.FFPM, Viton, 316 stainless steel and polypropylene are available.

Owning to our expertise in the application of different materials, motor types, and customization, while we customize the products that suit your specific needs, it also saves the cost.

We will work with customers to optimize liquid pulsation, a simple pulsation damper, which can reduce liquid pulses by up to 90% and is more economical than gear pumps.

Joto fluid’s products are suitable for barrier-free operation, and our unique, one-piece molded diaphragms are usually found only in larger, more expensive pumps.

With the higher requirements of the market, advanced printing equipment requires pumps of smaller, lighter, cheaper, and with built-in control systems. Joto Fluid solves these challenges with a variety of sophisticated methods.

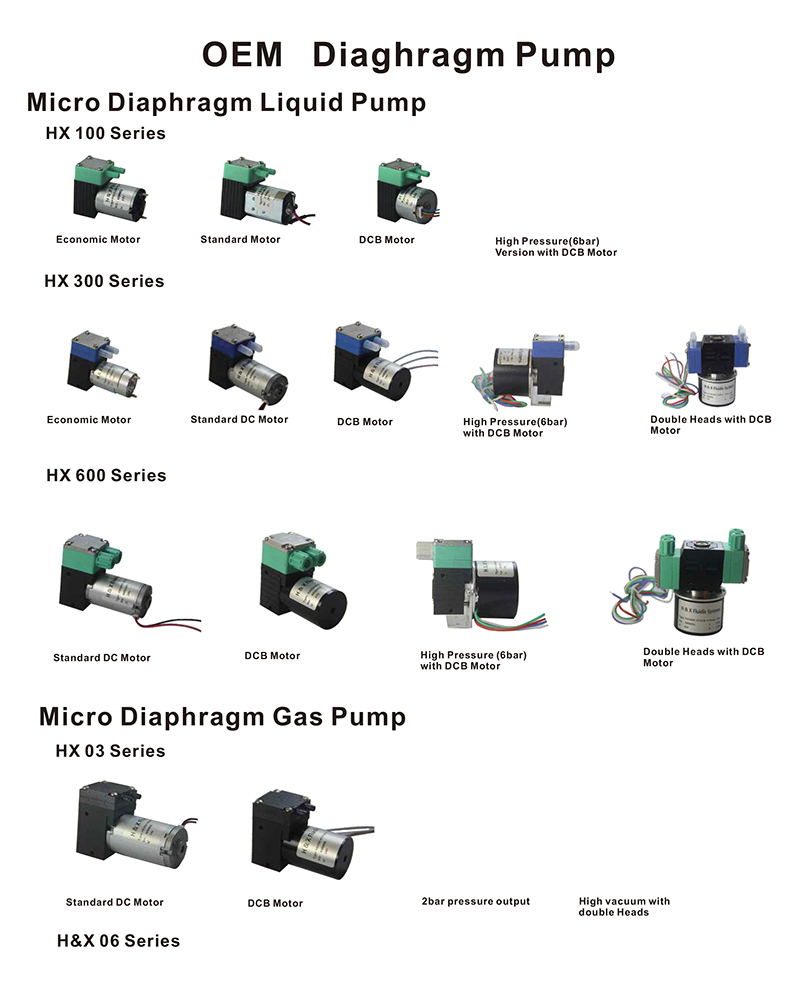

Brushed Motor (DC): With economical price and widely recognized reliability - brushed motors have served this field for many years. The pumping speed can be controlled through different voltages, usually in the 50%-100% range. However, the disadvantages of such brushed motors are: high commutator noise, carbon brush replacement, carbon brush dust and radio frequency interference (RFI).

Brushless DC Motor (DC): Unlike DC Brushed Motors. The brushless motor uses a quiet electronic driver. This method does not cause brush wear, no need to remove carbon brush dust, and no radio electromagnetic frequency interference. The brushless motor is very compact and the rotor is small, so it only requires a small inertia and starting current. Speed is easily controlled over a wide range of revolution speeds.

New control system: High-speed and continuous inkjet printers must adapt to a variety of complex and varied external environments, such as different ink types and printing speeds. Most our brushless motor controllers have the following features: fine speed control (analog and PWM Signal), logic on/off control, and feedback from some common speed signals (to achieve logical control of the printer). Joto Fluid is ready to embed our pumps into your printing system to achieve these exciting features.

Online shopping store: https://www.aliexpress.com

Contact: lina +86 15918770851 (WhatsApp)

E-mail: lina.jotofluid@hotmail.com

Name: Lina Hong

Mobile:+86 18998359638

Tel:+86 18998359638

Email:lina.jotofluid@hotmail.com

Add:14,1st Street,West District,Yujing Garden,Luoxi,Panyu,Guangdong, China